By:

Superway - Mar 25 - 2024

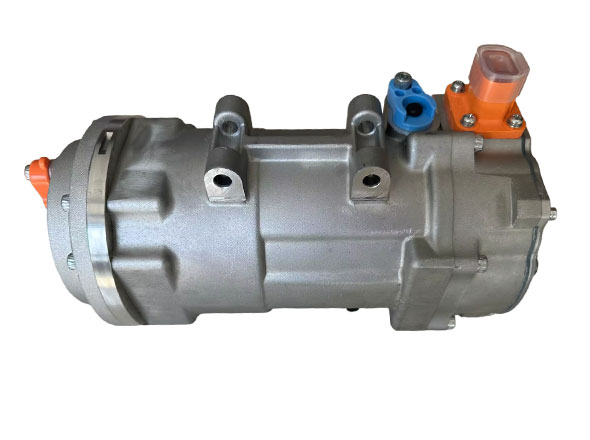

As new energy vehicles (electric buses and trucks) are gradually changing transportation and transportation methods, electric air conditioning systems are becoming a technical and performance problem that needs to be overcome. As an important component of the electric air conditioning system, the electric compressor is the most important technical barrier to the air conditioning system.

The 'heart' of electric air conditioners

As the "heart" of the electric air conditioning system, the electric air conditioning compressor achieves the cooling effect by compressing the refrigerant. In electric buses and trucks, electric compressors need to provide sufficient cooling capacity to meet in-car comfort requirements. At the same time, they need to take into account higher efficiency to minimize the use of battery energy and extend the vehicle's driving range.

Advantages of Electric Air Conditioning Compressor

Electric compressors have more obvious advantages than

traditional compressors. Electric air conditioning compressors are more efficient because they can be adjusted according to actual demand, reducing energy waste. In addition, their lightweight design helps reduce vehicle weight and space ratio. These advantages make electric compressors an important component of air conditioning systems, achieving high performance and sustainability.

Electric compressors in air conditioning systems and vehicles

Electric air conditioning compressors play a key role in the air conditioning systems of these large electric vehicles. They ensure that drivers and passengers can enjoy a comfortable interior in all weather conditions without placing a strain on the vehicle's battery life. This is crucial for long-distance transport and city bus services, increasing the availability and attractiveness of electric buses and trucks.

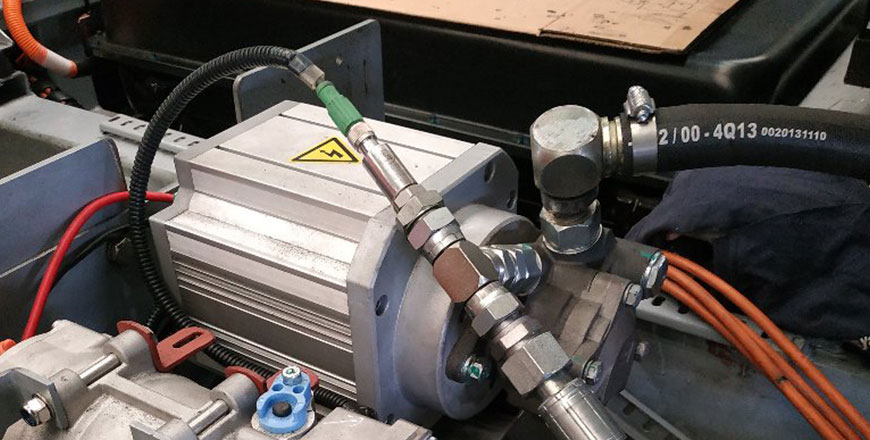

Installation of electric air conditioning compressor

Fixed compressor position:

Install the electric compressor on a base or bracket specially designed to fix the compressor (this base needs to have good corrosion resistance) to cope with different environmental conditions.

Connecting pipes:

Connect the compressor to the pipes of the air conditioning system. This includes intake lines, exhaust lines, and cooling lines. These pipes are made of materials that are resistant to high pressure and temperature to ensure the safety and reliability of the system.

Electrical connection:

The electric air conditioning compressor needs to be connected to the vehicle's electrical system. The devices that need to be connected include the power supply and the electronic control unit of the air conditioning system. For the compressor to operate properly, the electrical connections need to be made correctly.

Refrigerant filling:

After the compressor is installed, the electric air conditioning system needs to be filled with refrigerant. The refrigerant is filled with professional equipment to ensure that the amount of refrigerant in the system meets the specification requirements and does not leak into the environment.

Testing and calibration:

After the above steps are completed, system testing and calibration must be performed to ensure that the electric air conditioning compressor is operating properly and that the electrical system and control system are working properly.

The electric compressor is used in the air conditioning system of new energy vehicles. It has high energy utilization and is powered by batteries to meet the requirements of new energy vehicles. In addition, they feature compact, lightweight designs to accommodate the space constraints of electric vehicles and reduce the weight of the entire vehicle, thereby improving the energy efficiency and performance of electric vehicles. They are part of technological advancements in electric vehicles that help drive the development of sustainable transportation.

Leave a Reply

Your email address will not be published. Required fields are marked *