Electric AC Compreesor

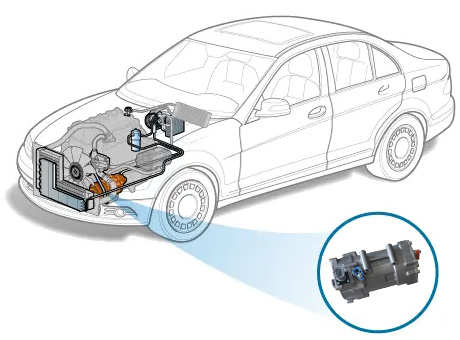

An electric air conditioning compressor, also known as a refrigeration compressor, is a device driven by an electric motor and is mainly used for the refrigeration cycle process in the refrigeration and air conditioning systems of electric vehicles. Its basic function is to inhale low-temperature and low-pressure refrigerant gas, increase the temperature and pressure through mechanical compression, turn it into high-temperature and high-pressure gas, and then release the heat through the condenser to condense it into a liquid, and finally reduce the pressure through the expansion device. Return the refrigerant to the evaporator to complete the refrigeration cycle. This process results in air or liquid cooling to achieve a refrigeration or air conditioning effect.

Application Scope

|

Electric AC compressors play a key role in automotive air conditioning systems, including: |

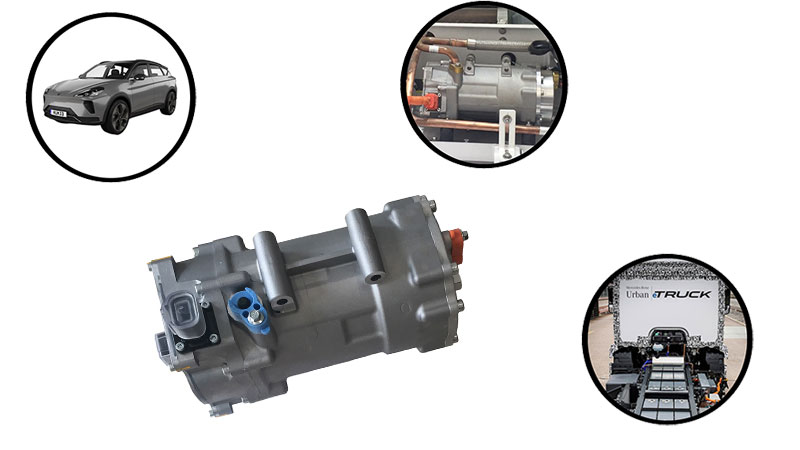

New energy vehicle air conditioning system:

Electric truck air conditioning system:

Electric bus air conditioning system:

Engineering machinery vehicle air conditioning system:

|

|

Used to cool the air inside the car, provide a comfortable driving environment for the driver and passengers, and ensure a comfortable temperature. |

Electric air conditioning compressors are suitable for a variety of vehicles and models. The specific application depends on the refrigeration needs and design requirements, including but not limited to the following situations:

a. Small cars: Small cars usually use 12-volt electric compressors to provide comfortable air conditioning for passengers. The cooling capacity is usually moderate and suitable for the cooling needs of small vehicle interiors.

b. SUVs and trucks: Large SUVs and trucks usually require electric compressors with larger cooling capacity to meet the larger interior space and cooling needs. These models may use 12 volt or 24 volt power, depending on the design.

c. Commercial vehicles: Commercial trucks, vans, and public transportation often require high-capacity electric compressors to sustain the cooling needs of multiple passengers or cargo. They usually use 24 volt power supply.

In summary, the cooling capacity and voltage of an electric air conditioner compressor depends on the vehicle type, size, and design, as well as the cooling needs. Different vehicles and models will be equipped with electric compressors suitable for their requirements.

Technical Specifications

The cooling capacity and voltage of the electric air conditioning compressor, specifications will vary between different vehicles and models. The following is a detailed introduction to the compressor cooling capacity and voltage:

1. Refrigeration capacity:

Cooling capacity is a key parameter that measures compressor performance and is usually expressed in feet per minute (CFM) or kilowatts (kW). The cooling capacity of a compressor depends on several factors, including its design, compression capacity, and operating conditions. Refrigeration capacity represents the volume or power of refrigerant gas that can be discharged from the compressor per minute.

2. Voltage:

Voltage standards for electric air conditioning compressors vary depending on vehicle type and power supply system. The main voltage standards include

a. 12-volt DC power supply: Many small and medium-sized cars usually use a 12-volt DC power supply, so their electric compressors are usually designed to work with this voltage standard.

b. 24-volt DC power supply: Some large cars, trucks, and commercial vehicles use 24-volt DC power supply, so they require compressors suitable for this voltage.

c. High-voltage power supply: In some special air conditioning systems, we can increase the maximum voltage of the electric compressor to 540v.

Working Principle

The

automobile electric compressor is the core component of the

automobile air conditioning system, and its working principle is based on the basic principle of the refrigeration cycle.

Evaporation: (The process of refrigeration cycle starts in the evaporator) -> Suction and compression: (The evaporated refrigerant enters the electric compressor in the form of gas) -> Condensation: The high-pressure and high-temperature refrigerant gas leaves the electric compressor and enters the condensation evaporator -> Expansion: the condensed refrigerant liquid enters the evaporator through the expansion device -> Repeat the cycle

The refrigeration effect is achieved by continuously changing the refrigerant from a liquid state to a gas state, and then compressing and condensing it again.

Scroll electric compressor

Working principle of scroll compressor

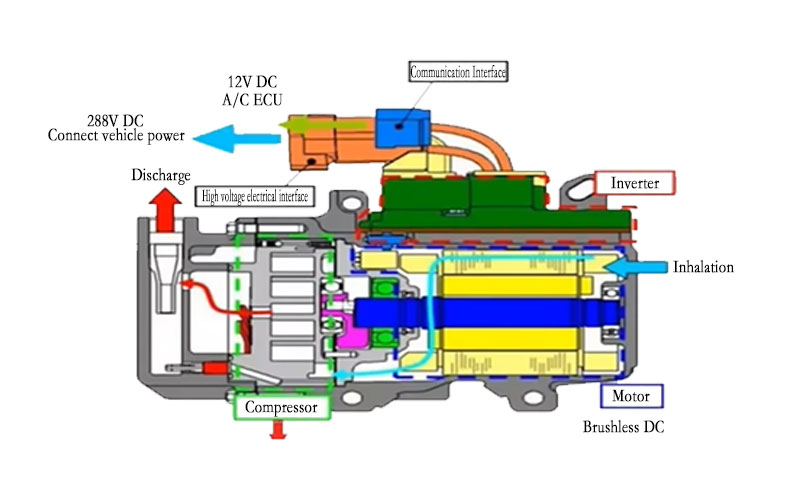

SW electric compressor is a scroll compressor. The compression component consists of a moving scroll and a fixed scroll. Its working principle is to use the relative revolution of the dynamic and static scrolls to form a continuous change in the closed volume to achieve the purpose of compressing gas.

Two movable scrolls and fixed scrolls with bifunctional equation profiles are 180° opposite to each other and mesh with each other. The movable scroll is driven by a crankshaft with a small eccentricity and is restrained by an anti-rotation mechanism to revolve around the stationary vortex. The disk moves in a plane with a very small radius, thereby forming a series of crescent-shaped cylinder working volumes in cooperation with the end plates.

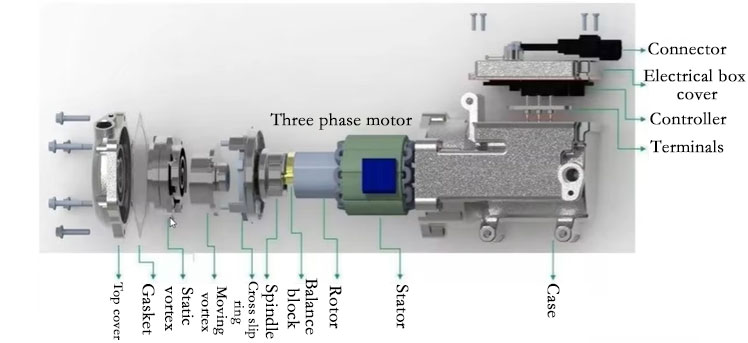

Scroll compressor structure

The electric compressor consists of a top cover, sealing gasket, static scroll, moving scroll, cross slip ring, main bearing seat, balance weight, rotor, stator, shell, glass terminal block, controller, electrical box cover, connectors, etc. composition.

It can be roughly divided into dynamic and static disk components, permanent magnet synchronous motors, and controller components. It includes machinery, motors, and inverter control boards. It is an electromechanical composite unit.

Refrigerant Selection

|

|

R-134a |

R-1234yf |

R-744 |

|

Thermal properties |

It is a hydrofluorocarbon with good refrigeration properties and can achieve efficient refrigeration at appropriate temperatures and pressures. |

It is a low-temperature refrigerant with good refrigeration properties, similar to R-134a. |

It is a natural refrigerant with excellent thermal properties that provides efficient refrigeration over a wide range of temperatures and pressures. |

|

Environmental protection |

Under certain conditions, it has a greenhouse effect on the atmosphere, but it is relatively low. However, it is considered a more environmentally friendly refrigerant because it does not damage the ozone layer. |

Considered a more environmentally friendly option because its greenhouse gas potential is much lower than R-134a. |

It is an environmentally friendly refrigerant as it does not adversely affect greenhouse gases or the ozone layer. It is a renewable natural gas. |

|

Compliance |

It is a common refrigerant in automotive air conditioners but has been restricted in some areas because of its greenhouse gas potential. As a result, some regions have already or are phasing it out in favor of more environmentally friendly refrigerants. |

Became a legal requirement in some areas to replace R-134a to reduce adverse effects on the atmosphere. |

has become a popular choice, especially in the European market. It complies with various environmental regulations. |

|

Application requirements |

Suitable for some car air conditioning systems, but in many places modern cars are required to use more environmentally friendly alternatives. |

Modern automakers have begun adopting R-1234yf, especially in European and North American markets, to comply with environmental regulations. |

It is an environmentally friendly choice, but it requires higher working pressure and specific technology for the car air conditioning system, so it is usually used in high-end and advanced car air conditioning systems. |